Moisture Issues: Basements are prone to moisture-related problems such as water seepage, condensation, and high humidity. Epoxy coatings can be susceptible to moisture-related issues, including peeling, bubbling, or delamination.

Surface Preparation: Proper surface preparation is crucial for successful epoxy application. The concrete surface needs to be clean, dry, and free of cracks, oil, grease, or other contaminants. Achieving the necessary level of preparation can be time-consuming and labor-intensive, requiring thorough cleaning, patching, and potentially etching or grinding the surface.

Difficulty in Application: Applying epoxy coatings can be a complex process that requires skill and experience. It involves mixing different components, applying the epoxy evenly, and dealing with potential issues like air bubbles or uneven drying. Inexperienced individuals may struggle to achieve a professional-looking result, leading to a less desirable outcome.

Limited Design Options: Epoxy coatings flooring typically provide a glossy, seamless finish that can enhance the aesthetics of a basement. However, the design options are limited compared to other flooring alternatives. If you have specific design preferences or want a different texture or pattern, epoxy flooring may not offer the flexibility you desire.

What Everyone Ought To Know About EPOXY BASEMENT FLOORING

Enhanced Durability: Epoxy basement coatings are known for their exceptional durability. They create a strong and resilient surface that can withstand heavy foot traffic, impacts, and abrasions. This makes epoxy flooring an excellent choice for basements, which often serve as high-traffic areas.

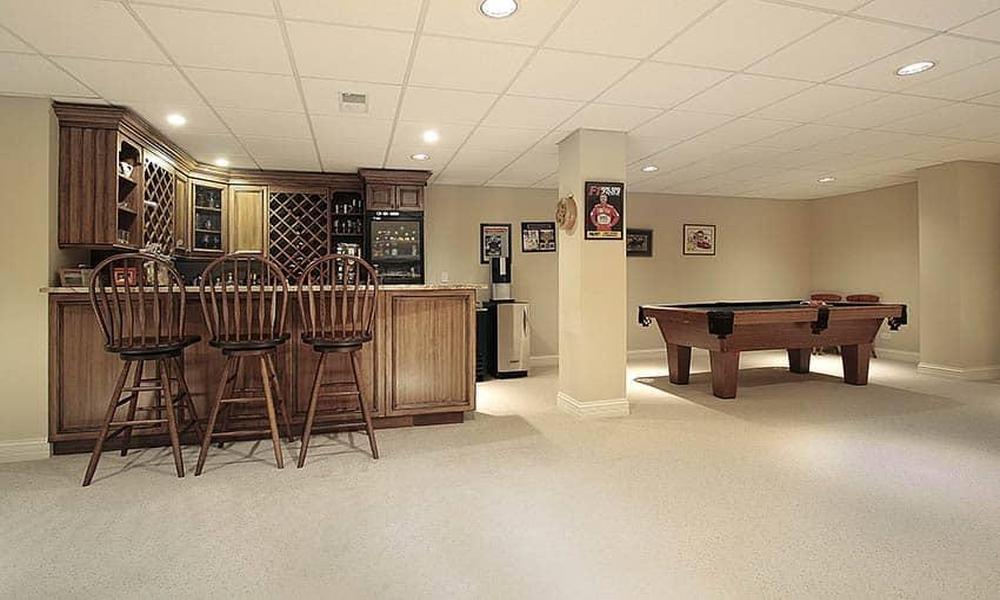

Improved Lighting: Epoxy floors have a glossy finish that reflects light, brightening up the basement space. This can be especially beneficial for basements with limited natural light, making them feel more open and inviting.

Longevity: When properly installed and maintained, epoxy basement flooring can last for many years. Its durable nature ensures that it can withstand the demands of everyday use and continue to look good over an extended period.

Curing Time and Odor: Epoxy coatings require a curing period before they reach their full strength. During this time, it’s essential to avoid heavy furniture placement and excessive moisture exposure. Additionally, epoxy coatings can emit strong odors during the installation and curing process. Adequate ventilation is necessary to minimize the odor and ensure a safe environment.

Unheard Ways To Achieve Greater EPOXY BASEMENT FLOORING

Concrete Moisture Mitigation: Basements can be prone to moisture issues, which can affect the performance of epoxy coatings. Before applying the epoxy, consider using a moisture mitigation system that reduces the moisture levels in the concrete. This can involve applying a moisture-blocking epoxy primer or using a vapor barrier system to prevent moisture from coming up through the concrete slab.

Glow-in-the-Dark Additives: For a unique touch, you can mix glow-in-the-dark additives with the epoxy coating. These additives absorb light during the day and emit a soft glow during the night, creating an intriguing effect in your basement. This can be particularly useful if you use your basement as a recreation or entertainment area.

These products penetrate the concrete surface, creating a translucent effect that enhances the natural beauty of the concrete. Stains and dyes come in various colors and can be combined to achieve custom patterns or designs, allowing for a personalized and artistic epoxy basement floor.