As 3D semiconductor packaging continues to revolutionize chip design, ensuring defect-free manufacturing has become increasingly critical. This advanced packaging technique, which stacks multiple chip layers, enables greater performance and miniaturization but also introduces challenges in detecting defects at nanoscale levels. Erik Hosler, an expert in semiconductor manufacturing and AI-driven process innovations, mentions how artificial intelligence (AI) is transforming defect detection and process optimization in 3D semiconductor packaging, reducing waste and boosting efficiency.

AI-Driven Inspection: Precision Beyond Human Limits

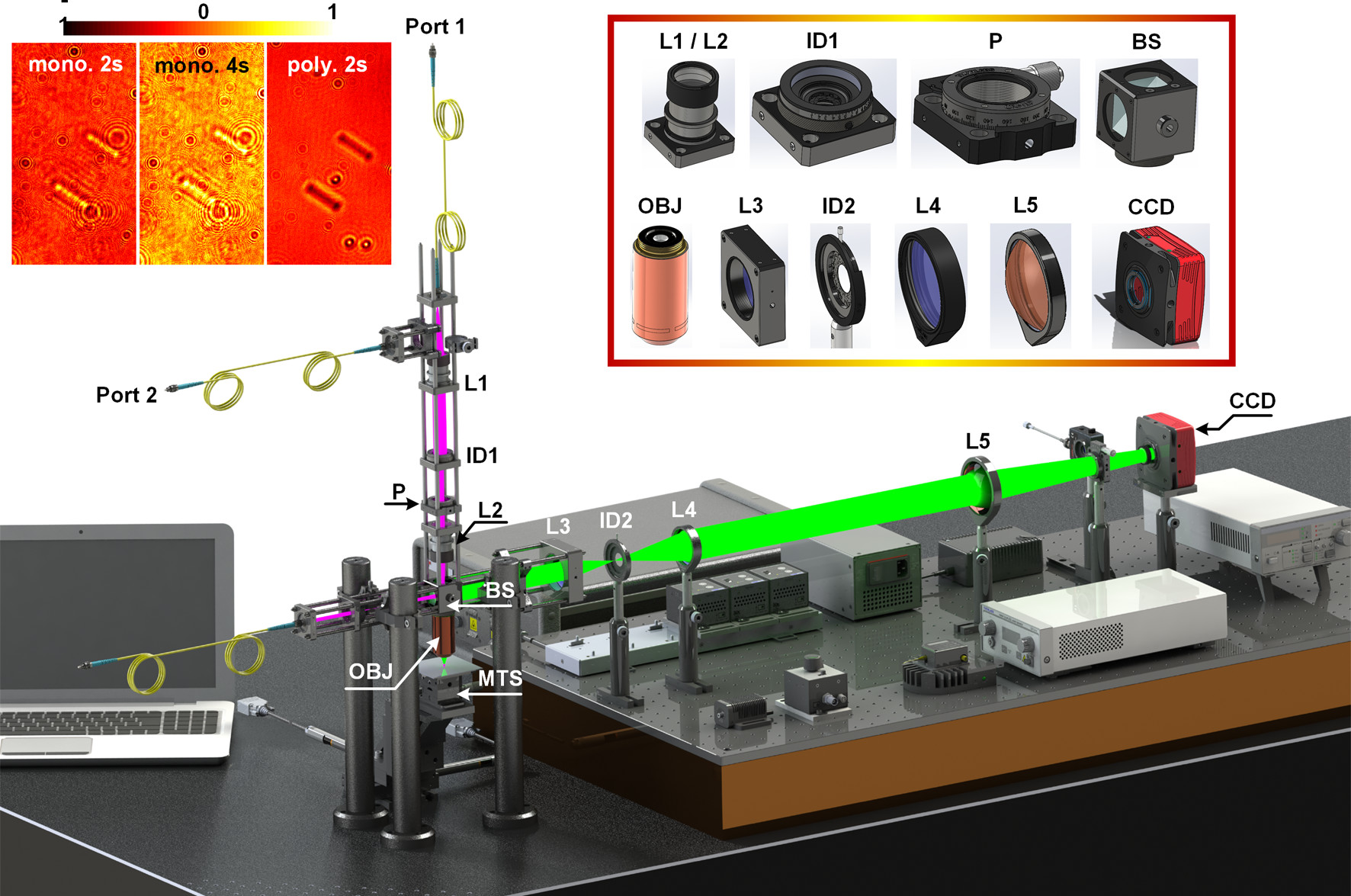

Traditional inspection methods often struggle to identify defects in 3D packaging due to the complex nature of stacked layers. AI-driven inspection systems address this challenge by employing machine learning algorithms that analyze massive datasets to detect subtle defects with unparalleled accuracy.

These systems use advanced pattern recognition to identify irregularities in bond connections, interconnects and through-silicon vias (TSVs)—areas prone to defects in 3D structures. By identifying potential failures early, manufacturers can reduce the number of defective chips that advance through production, significantly lowering waste and costs.

Real-Time Optimization: A Dynamic Approach to Efficiency

AI systems not only detect defects but also enable real-time process optimization. Machine learning models continuously monitor production parameters, flagging deviations that could lead to errors. This dynamic feedback loop allows fabs to adjust variables such as temperature, pressure and material deposition rates during production, ensuring higher yields and more reliable chips.

These insights also support predictive maintenance, reducing downtime by identifying equipment issues before they result in failures. By maintaining seamless production, AI ensures consistent quality and improved manufacturing efficiency.

Reducing Waste Through Smarter Processes

Waste reduction is a key benefit of AI-powered defect detection. By precisely identifying defective components early, fabs can focus resources on viable products and reduce the disposal of faulty materials. Erik Hosler emphasizes, “Accelerator technologies, particularly in ion implantation, are enabling manufacturers to push the limits of miniaturization while maintaining the integrity of semiconductor devices.” This intersection of AI and advanced technologies is critical for sustaining the growing demand for smaller, more powerful chips while minimizing environmental impact.

The Future of AI in Semiconductor Manufacturing

AI-powered defect detection is revolutionizing 3D semiconductor packaging by enhancing yield, reliability and sustainability. As these systems become more sophisticated, their ability to optimize processes and detect nanoscale defects will play an increasingly vital role in advancing semiconductor manufacturing. By integrating AI into production, the industry is paving the way for a future where innovation and sustainability go hand in hand.